The artificial stone material, processing technology, and on-site installation capabilities are important signs for testing the “maturity” of the kitchen cabinet company. It is also an important technical guarantee for the realization of the development direction of the kitchen cabinet industry that combines industrialization, commercialization, and individualization.

Artificial stone technology and installation are important components of kitchen cabinets.

Kitchen and bathroom countertops made of artificial stone have been favored by consumers. With the popularization of kitchen cabinets in the market, the use of artificial stone has also increased year by year. Like any marketable commodity, there have been uncountable “artificial stone” manufacturers all over the country, and the number of brands is dizzying. In view of the important position of artificial stone countertops in kitchen cabinets, it is very necessary for consumers to recognize artificial stone and evaluate the quality of the artificial stone. Therefore, consumers should master some basic common sense of artificial stone.

The quality of the artificial stone kitchen and bathroom countertops has two major elements. First, what are the material and properties of the artificial stone wool board itself? Second, how about the processing technology and control installation technology and capabilities? The two complement each other and are indispensable.

(1) What types of artificial stones are there?

1. Artificial stone is a “polymer of polymer material”, usually a “polymer solid board” formed by processes such as stirring, shallow injection, heating, and polymerization based on unsaturated resin and aluminum hydroxide filler. Generally called: “resin board artificial stone”.

2. Artificial stone with “methyl methacrylate” (MMA) as the main material, also known as acrylic artificial stone. With DuPont of the United States as the representative, a few domestic professional companies such as Yadir can also produce “acrylic” artificial stone at the same time.

3. MMA, resin mixed artificial stone, known as A-board in Yadir, is the first practical artificial stone to be promoted in the industry between the above two kinds of artificial stone.

4. There are also many artificial stones priced between 400-600 yuan per meter on the market. According to the normal quality requirements of artificial stone and the price of raw and auxiliary materials that can guarantee the quality, the cost calculation shows that the two main materials of the artificial stone may cut corners, use low-cost resin, discard aluminum hydroxide and use calcium carbonate. Instead, it is the main means to reduce costs. Known as calcium carbonate artificial stone, about 95% of the artificial stone on the market is inferior calcium carbonate artificial stone (there are also many artificial calcium carbonates sold at high prices, which is even more deceptive).

(2) How to identify the quality of artificial stone?

The quality of artificial stone countertops consists of two aspects: one is the quality of artificial stone slabs, and the other is the comprehensive technology, experience, and ability of artificial stone countertops processing technology and on-site control capabilities. The former can be identified by observation and comparison, but the latter is not easy to identify.

“Cheap is not good” in theory, consumers can readily accept it, but in the process of purchasing, due to price temptation, because they don’t understand the difference in cost and quality of artificial slate, they tend to be tempting. Tempted by the low price.

Inferior calcium carbonate artificial stone will not only show signs of inferior quality such as color difference and deformation but also cause the rough board after polymerization to volatilize harmful gases to the human body due to process defects.

(3) “Shop around” can compare the pros and cons of the processing level

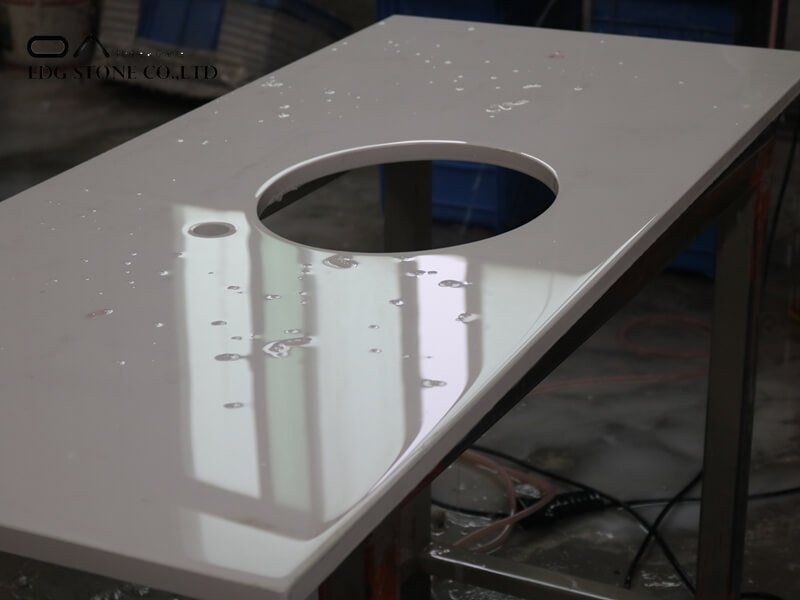

From the appearance, you can compare the processing level and the pros and cons with the method of “shop around”. First, look at the “straight line” of the artificial stone countertop. From left to right, or from right to left, the straight line along the edge of the countertop shows whether the craftsmanship of “sawing, cutting, bonding, and forming” is fine. Second, look at whether the four-sided joints of the under-counter basin of the stainless steel sink are delicate, round, and natural. Whether the milling shape of the milling part is properly proportioned. Third, whether the downturn thickness of the tabletop is uniform. Fourth, whether the lines of the rear bumper are round and delicate. Is it natural? Fifth, what is the polishing condition of the countertop, how flat is it, and whether there is any color difference visible to the naked eye.

(4) How to identify the processing level of artificial stone?

Due to technical capabilities, the general kitchen cabinet company always installs the cabinet body first, then measures the countertop size, returns it to the factory for processing, and then installs the artificial stone countertop after about 5 days or a week. Tossing back and forth, the entire installation cycle lasts from 5 to 10 days, which fully reflects the defects of “low technical ability” and “low professionalism”. It is often inevitable that a certain part of the countertop is large or small and cannot be installed. , Quality problems such as too obvious chromatic aberration in the splicing gap.