Stone countertops mainly include granite countertops, marble countertops, sandstone countertops, slate countertops, limestone countertops, and quartz stone countertops. The mainstream of them are granite and marble countertops. In terms of production quantity and application scope, Granite countertops are the most widely available.

The main processing flow of stone countertops is:

Material selection → Large cutting → Polishing → Trimming → Edge processing → Digging and drilling → Polishing and repair → Trial assembly inspection → Packaging → Completion

01. Select materials

Stone blocks and slabs

Select suitable rough materials based on customer samples or production order requirements. It is best to knock a small sample of the blocks for polishing comparison and observe whether the pattern, color, and particles are consistent. If the countertop is of regular thickness, you can also purchase large boards directly from the large board market. The important point to note when selecting materials is to choose blocks or slabs with the same color, pattern, grain, and close density. At the same time, defects such as cracks, gallstones, color lines, and flower sweeps are not allowed in the appearance. At the same time, attention should be paid to the thickness and size of large boards.

02. Big cut

It is the process of cutting raw materials into rough boards with a circular saw or sand saw according to the customer’s processing requirements. After cutting, an inspection must be carried out first. Qualified rough boards are retained, unqualified ones are picked out, and extra-thick rough boards are subjected to post-processing. (If you are purchasing a large board, you can skip this stage.)

stone blocks cut into slabs

03. Polishing

The polishing stage is divided into two parts: coarse grinding and fine grinding.

granite slabs for countertops

Rough grinding: The products that have passed the previous process and the rough boards with fixed thickness are first rough ground with a grinder. At present, the grinders are mainly hand-held grinders and multi-head continuous grinding and polishing machines.

After the rough board is dry, check the board surface. If the surface effect is good, you can directly grind it finely. If you find that the quality of the rough board surface is not ideal, you can brush the surface of the rough board with glue and apply a layer of resin glue to seal it. The small holes, small cracks, chicken claw marks, and other defects on the rough board can be repaired, which can also make the rough board surface better and glossier.

When the weather is good, the resin can usually dry in more than half an hour. If the weather is bad, it will take about 1-2 hours to dry. It is best to wait until it is dry before finely grinding. Some factories clean and inspect the roughened boards without rough grinding, and then apply glue directly on the roughened boards (problematic ones). Usually, granite is brushed less, and marble is brushed more.

Fine grinding: Use a polishing machine to polish qualified rough boards or repair rough boards piece by piece into matte boards. Remember to use red crayons to remove irreparable cracks, light colors, stone galls, scratches, and other defects in the matte boards. Mark them on the board so that they can be discovered in time in the next process, and these defects can be avoided by processing small-sized components, such as water shields or thickened edges, etc.

Usually, the glossiness requirement for European and American orders must be above 90° (or processed according to customer requirements. If some stone types do not meet the requirements, we must negotiate with the customer). At the same time, the flatness limit tolerance of European and American standard matte boards is 0.8MM, and the allowable tolerance value of the thickness limit tolerance is plus or minus 1MM.

04. Trimming

The qualified roughened boards in front are laid out and cut according to the requirements of the production order, and each part of the table panel is cut out–the main table top, back baffle, side baffle, front baffle, etc.

stone countertop edges cut

When cutting, you should pay attention to check the surface before cutting, pay attention to the stone defects marked before, avoid cracks, black spots, color lines, stains, sweep flowers, etc., and do not have yin and yang sides.

At the same time, it is necessary to ensure that the geometric dimensions, angle dimensions, and diagonal dimensions of the finished product after cutting are accurate, and no chipping or falling corners are allowed. If the back of the countertop needs to be bonded, the edges, edges, and corners on the back should also be kept intact to facilitate subsequent edge processing.

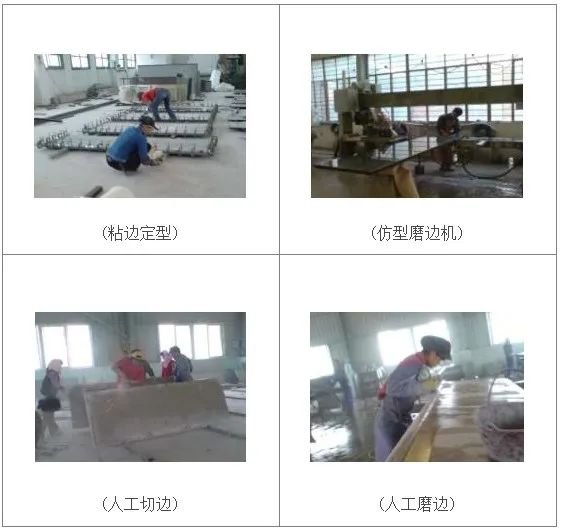

05. Edge processing

Edge processing is processing the edge of the countertop, whether it is simply grinding the edge straight or processing it into a special-shaped edge (cow nose edge, duck bill edge, etc.).

stone countertop edges work

If the customer does not require the sides to be thickened, the countertop can be directly processed (edged). If the customer requires thickening of the sides, then the sides of the countertop must be thickened first.

The specific method is to use a small cutting machine to smooth the area to be added, and then roughen the bonding surface into a rough surface for a stronger bond. Then apply glue to bond, and finally use clips to shape and clamp it.

Pay attention to the gap between the two boards on the bonding surface as small as possible when bonding, preferably 0.1 to 0.2 mm. After the glue dries, the edge processing can be carried out. Advanced factories use special profiling edge grinding machines with artificial polishing assistance, while ordinary factories use manual cutting.

06. Digging potholes

stone countertop edges polishing

It is to open the wash basin mouth, faucet hole, and the installation hole of the under-counter basin on the countertop. The opening is usually made by machine, and the mouth of the basin is usually opened manually, or the four corners of the wash basin are first opened by a machine and then cut manually.

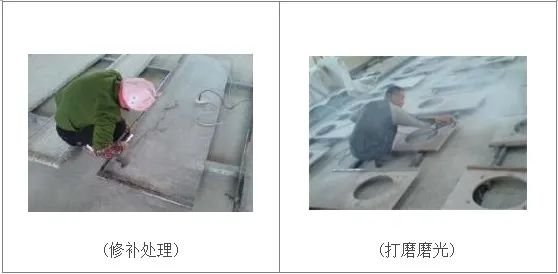

07. Polishing and repair

Repair is to repair damage caused by careless processing (slight unevenness or missing corners, etc.) or other natural defects. Pay attention to using glue that is close to the color of the stone.

stone countertop sink cutout

Polishing is to polish the smooth surface of the entire countertop. The gloss after polishing must be above 90°. At the same time, the surface must have a mirror gloss, no unevenness, no wavy lines, and the straightness of the intersection should be maintained in a straight line. The glossiness of the countertop edge and wash basin mouth should also be consistent with the sky surface. It is usually ground with a hand grinder. If the effect is good, it can be ground with a large grinder.

For countertops that are composed of multiple parts, they must be pieced together, repaired, and polished to avoid problems during the trial assembly.

08. Trial assembly inspection

The countertops will be inspected piece by piece, and any unqualified products will be promptly replaced or reworked. At the same time, in addition to the smoothness of the edges, the feel and the flatness of the boards, etc., for the combined tabletops that are not a single product, it is also necessary to try to put them together. Pay attention to the unity of the colors of the combined tabletops, the degree of fit of the interfaces, and the combination. The left and right order must be accurate according to the drawing.

stone countertop layout and QC

If the stitching effect is not good, it must be reworked, and if the pattern and color are not uniform, it must be replaced.

Also, if the opening of the washbasin is only 7 or 200px from the edge, it needs to be reinforced with steel bars. Even if this distance is exceeded, steel bars must be reinforced at the back if requested by the customer. After the inspection, if the customer requires protection (waterproof treatment, etc.), protection can be done.

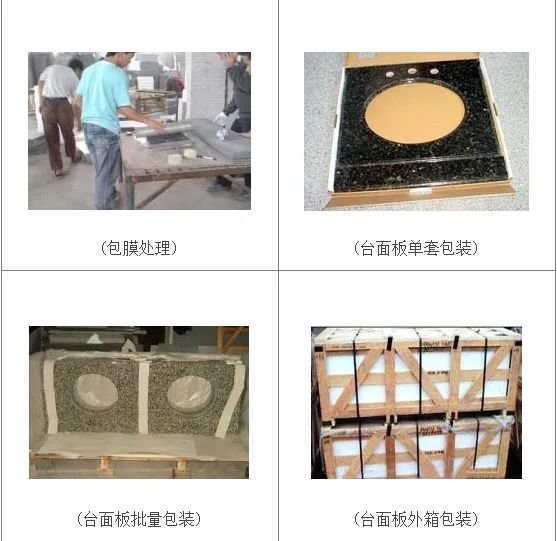

09. Packaging

When packaging, the products are packaged according to customer requirements or stone quality. The blunt surfaces are opposite to each other, and a scratch-proof soft film is sandwiched between the smooth surfaces.

stone countertop packings and shiping

As for some stones that are afraid of scratches, such as stones with darker colors (such as Shanxi black), they will be coated to prevent scratches from affecting the visual appearance. Countertops should be placed vertically so that the stone is stressed vertically. Never place them horizontally.

It is best to tie all the countertops into a whole with packing tape and do not loosen them. Finally, it’s done, the countertop is now produced packaged, and ready for shipment.